- 586-445-1593 Monday - Friday 8am to 4:30pm & Saturday 8am - 12pm

- Shipping & Payment

- Order History

- Log In

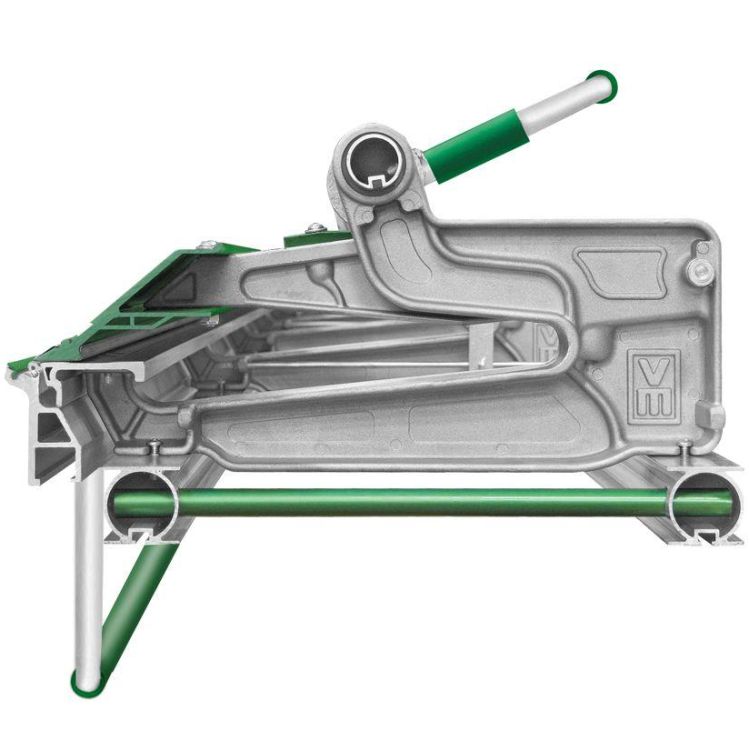

Brake shown with optional unilegs

Building upon the reputation of the Mark I Series, the Mark II TrimMaster arrives with leading technologies such as the PowerSlot technology for easier bending, making smaller “J” channels and hollow core hinge extrusions for added strength. We've also left you the ability to make fine-tune adjustments to this brake, though you may never have to. Ultra High Molecular Weight wedges are independently adjustable and replaceable should the occasion ever arise. After all, we believe a Van Mark brake is the closest thing to a “non-adjustment” brake you'll find out there.

Van Mark Model No. TM10HD-S

POWERslot™ Hinge

The POWERslot™ was developed for two reasons: to increase the strength of the hinge and to allow smaller bends. The result was the POWERslot™ hinge that features a hollow core extrusion to provide unmatched strength and free-motion hinge that “auto-measures” at 5 ⁄ 8". The free-motion feature allows the POWERslot™ to keep a targeted, maximum pressure on the material throughout the entire bend. Comes standard on Mark II TrimMaster®, Mark IV Industrial TrimMaster®, Metal Master® 20, and Industrial Metal Master®.

| Common Bending Capacities | |

|---|---|

Aluminum Coil |

.040"

|

Galvanized Steel |

24 ga.

|

Stainless Steel (304L) |

26 ga. |

Zink Alloy |

.040" |

Roofing Copper |

32 oz.

|

Capacities are based on standard metal properties for coil and sheet